|

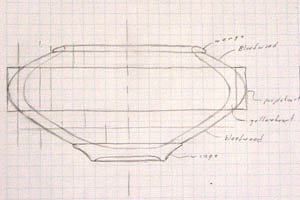

Design Here is the plan.

Hopefully, it'll turn out pretty close.

|

|

Materials Luckily, I was

able to find enough of all the woods I wanted to use.

Some of it was leftovers from other projects, but this'll

put them to good use. Here is some wenge, bloodwood,

yellowheart, and purpleheart.

|

|

Preparing the Stock I

ripped the stock to all the thicknesses that I'll need.

|

|

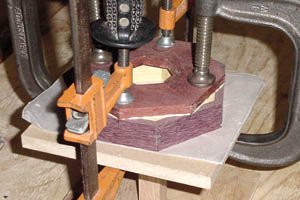

Laminating the pieces for the ring with

the ovals The thinner purpleheart layer

will form the ovals and the thick yellowheart will be the

background.

|

|

Ready for cutting The

laminating is complete. A little planning allowed me to

use the scrap purpleheart strips. I'll have just enough

to get the number of segments needed. (3 out of the top

one and 4 out of the bottom.)

|

|

Cutting I almost forgot to

take a picture. This is the last piece of the oval

section just after being cut. The picture shows my setup.

Not pretty, but it works. I make test cuts on some scrap

pine to get the saw adjusted precisely before I started

cutting on the real thing. The cuts have to be perfect

for the ovals to come out right.

|

|

All pieces cut This shows

all of the pieces cut and laid out nicely for the

picture. I usually start gluing before I get all the

pieces cut, but it's easier to show this way.

|

|

Gluing the rings Here all

the rings are glued and clamped with rubber bands.

|

|

Stacking the rings The

rings are centered and glued together to form the blank

|

|

More stacking Normally, on

most open bowls this process would continue until all of

the rings are stacked. Since the centering must be

perfect on the layer with the ovals I'll turn this bowl

in two sections leaving the critical "oval"

layer on the outside of one section. This will allow for

perfect centering and help in the hollowing process.

|

|

The blanks Here are the two

sections completely glued. The bottom layer (on the

right) has a scrap block glued to the bottom and a

faceplate attached, but I'll start turning the top

section first (the one on the left).

|

|

Making an auxilliary faceplate A

scrap piece of plywood is mounted to the faceplate. I

turned a short spiggot on the plywood just large enough

for the "oval" ring to fit over with a snug

fit. This is not to hold the blank, but it will insure

that the ring will be perfectly centered and won't slip

out of place. I put pieces of double stick tape on the

faceplate to actually hold the blank.

|

|

Mounting the first section This

shows the top section mounted and ready to turn.

|

|

Turning While the blank is

being roughed out the ovals begin to form.

|

|

Getting the ovals right I

go ahead and shape the bowl using the ovals as a guide

when to stop. I hold off on shaping the rim at this

point, because I'll need that area for holding the piece

when I turn it around to do the inside. I did go ahead

and round out the center of the rim and true up the face

for the next step.

|

|

Another auxilliary faceplate This

could have been the first auxilliary faceplate with the

spiggot turned smaller to fit the hole in the rim just

turned. This one was just made from another piece of

scrap. More pieces of tape will hold the blank.

|

|

Reversing the Blank The

blank is removed from the other aux. faceplate and

remounted in reverse to this one so that the inside can

be turned.

|

|

Turning the inside The

inside is turned to final thickness with a tad extra left

on where the two sections will be glued together. This

will finish up the hollowing for this section except for

the joint where the sections are glued together. I went

ahead and sanded the inside at this time.

|

|

Mounting the bottom section The

other section doesn't have to be centered as precisely as

the section with the "oval" layer, so I can

start turning it as I have it mounted already.

|

|

Turning the outside I

shaped the outside to near final dimensions except for

the base, which I wanted to have wider for more support

during the turning process. I did go ahead and get the

top close to the final diameter. I stopped the lathe

frequently and matched the top section to the bottom so

that I could get the diameter and curvature just right.

|

|

Turning the inside I turned

the inside to match the outside.

|

|

Putting the two sections together Leaving

the bottom section on the lathe and with the top section

still attached to the aux. faceplate I glued the two

sections together being careful to line the joints up to

match the alternate layer on the opposite section. The

tailstock provides a nice clamp for the two sections, I

just have to make sure that the two sections remain on

center until the glue sets.

|

|

Clean up the glue joint I

removed the aux. faceplate from the rim and cleaned up

the transition between the two sections, so that the

curve flowed smoothly and there is no distinction between

the two sections.

|

|

Turning the rim Here the

rim is turned to the final shape, and the joint between

the two glued sections is cleaned up on the inside.

|

|

Turning the base Well, I

can't really get to the base very well, but this shows

where I shaped it to very near the final shape. Sanding

is completed at this point on all parts except for the

base.

|

|

Getting ready to finish the bottom Now

that I have put all this effort into this project and it

has turned out so well to this point I surely don't want

to have the bowl fly off the lathe and bounce across the

shop floor. So, I'll put a little extra effort into

holding the bowl, since I'm doing this without the use of

a chuck. I make a sort of jam chuck by turning a shallow

spiggot on the scrap wood to press fit inside the rim,

and I drill a hole for a bolt to go through the center.

|

|

Making the cleat Actually,

I had this one already made. I have used it once or twice

before, so I didn't want to make another one. It's just a

piece of scrap wood rounded and sanded with some tape on

it to cushion the area that will be against the bowl. A

hole is drilled in the center and countersunk to hold a

long bolt.

|

|

Attaching the cleat I did

this with the faceplate off the lathe. The picture just

shows how the cleat will be oriented once it's inside the

bowl. The bowl is slipped over the cleat and a nut is

tightened onto the bolt that protrudes through the

backside of the faceplate.

|

|

Mounting the bowl Here is

the bowl mounted on the reinforced jam chuck, or whatever

you want to call it. It is actually sturdy enough for

some fairly heavy turning, but there's none of that left

to do.

|

|

Turning the bottom Now the

bottom can be turned to the final shape and sanded. This

completes the bowl except for the finish.

|

|

Turning completed Here's a

view of the freshly turned bowl. All that's left is a few

coats of wipe on poly.

|