|

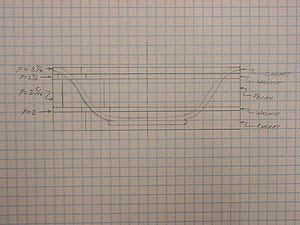

Design I begin by sketching

the bowl profile on grid paper. I also decide at this

point which woods to use, the thickness of each layer,

and how many segments I want the pattern to be based on.

|

|

Materials I then try to see

if I actually have enough of each type of wood to finish

the job. This time it was easy since this will be a small

bowl. These are some scraps that I had laying around the

shop waiting for a project like this one. (Walnut,

cherry, and spalted pecan)

|

|

Preparing the Stock I rip

the stock to the thickness that I'll need for each layer.

The square piece at the upper right will be the bottom

layer which will be solid. The small pieces at the lower

left will be inserted between the segments of the middle

layer. (We'll get to that part later.)

|

|

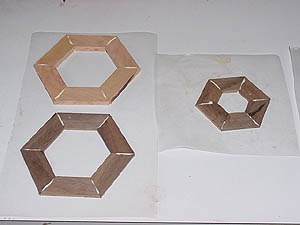

Cutting & Fitting the Segments I

failed to take a picture before I arranged the segments,

but the segments were just cut with a miter saw. This

picture shows the cut segments dry-fitted on a sheet of

sandpaper. This way I can determine how much sanding I

have to do to get a perfect fit. A slight touch up on the

disk sander on selected segments will get perfect joints.

|

|

Getting the Perfect Fit Here

are the segments arranged again after sanding to get the

joints fitting perfectly. Also, the segments in the ring

on the upper right was cut too thick to make better use

of the scrap block it was cut from. I then ripped them

down afterwards to get closer to my design. This saves a

lot of roughing out when the blank gets to the lathe.

|

|

Gluing the Segments Here

some of the segments have been glued into rings and are

waiting to dry. With thin segments I just use hand

pressure to press the segments together.

|

|

Gluing Larger Segments Here

is the middle layer with the straight pieces glued

between the mitered segments. Since it is large enough to

clamp I use a lot of cheap rubber bands to clamp the

ring. On even larger rings I sometimes use a band clamp.

|

|

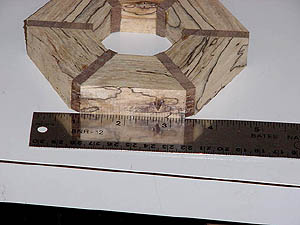

Flattening the Layers I use

a belt sander to flatten each side of the layers. This

gives perfect surfaces in order to glue the layers

together. There are many different ways this step can be

done, this is just how I do it. I hold the piece down on

the sander with light pressure with my left hand and keep

rotating it with my right hand until it is perfectly

smooth. Buy me a drum sander and I'll put it to good use.

|

|

Ready for More Gluing Here

are the layers after they have all been sanded smooth on

both sides. Notice that I cut out a disc for the bottom

layer, it was also sanded smooth on the belt sander.

|

|

Marking the Rings I decided

to start with the middle layer. Here I measured and

marked the center of each segment for reference points.

This will help to get the rings centered while gluing.

|

|

The lighter colored wood shows the marks very well.

Here the marks were extended to the upper surface (which

will be toward the bottom on the finished bowl) as well

as the sides. |

|

Checking the Match The

marks on the sides should line up with the joints of the

next layer. This centers the layers (unless you had to do

an excessive amount of sanding to get the joints to fit

in the ring), and it also separates the joints making

them less likely to fail under stress. Also, notice that

the grain in the straight walnut segments of the middle

layer lines up with the grain of the adjacent layer. This

makes the joint between them less visible and the

reflection of light will be nearly the same so you don't

readily notice that they are different pieces.

|

|

Gluing the First Layers Here

are the first two layers glued and clamped. I usually let

them cure for about 30 minutes before I go to the next

layer.

|

|

Gluing the Next Layer The

next layer is glued lining up the joints with the other

marks on the middle segment.

|

|

Gluing the Top Layer The

top layer (on bottom) is glued lining up the joints with

the segments of the middle layer.

|

|

Gluing on the Solid Bottom The

solid disc is glued using the adjacent layer for

centering. If the disc had been significantly smaller

than the next layer then marks would have to be made to

get the centering correct.

|

|

Mounting the Blank Now,

finally I have a blank to work with. Next comes the fun

part. I mounted the blank on the chuck expanding the jaws

in the interior. For larger bowls I would temporarily

glue the top layer to a scrap block mounted on a

faceplate. Before I got the chuck I glued a scrap block

to the bottom of the blank with a paper joint and screwed

it to a faceplate.

|

|

Turning a Recess for the Chuck I

could have also gone ahead and shaped the outside of the

bowl at this point, but I wasn't comfortable with the

chuck security. (It's a 4 jaw chuck holding a 6 sided

piece.)

|

|

Re-mounting the Blank Here

I am using spiggot jaws in the chuck to hold the blank in

the recess I just made.

|

|

Turning the Outside Here

the outside is turned. Not necessarily an exact match to

the original design but close, and I like it.

|

|

Turning the Inside I turned

the inside to match the outside with about 1/8 inch of

thickness and tapering thinner toward the rim.

|

|

Sanding Here the inside and

outside are sanded to 220 grit. I would have gone finer,

but I was out of 320 grit. It still looked pretty good

like it was.

|

|

Finishing I applied a coat

of friction polish to the bowl as it was spinning. This

is not my favorite finish, but it looks pretty nice and

is very quick. Other finishes have to be applied after

the bowl is completed.

|

|

Turning the Base I made a

jam chuck to hold the bowl in order to turn the base.

This chuck has been used before and will be used several

more times before it is discarded. I used a piece of

rubber drawer liner to hold the bowl in the recess. This

was the first time I used it, and it worked great. It's

really cheap too. A paper towel will also work.

|

|

Finishing the Base After

turning and sanding the base I applied a coat of friction

polish to it. Now the bowl is finished.

|